Dec 7, 2022

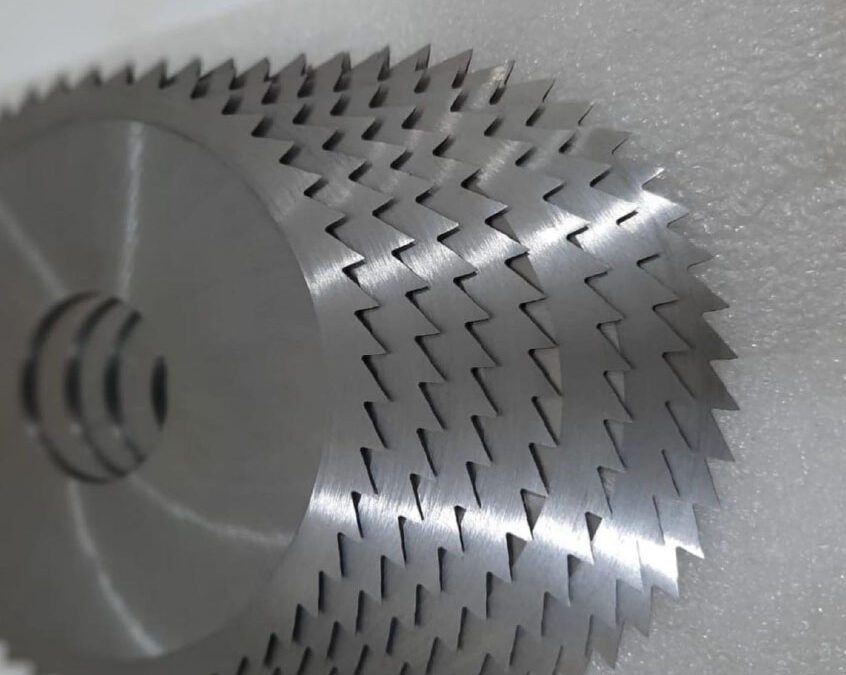

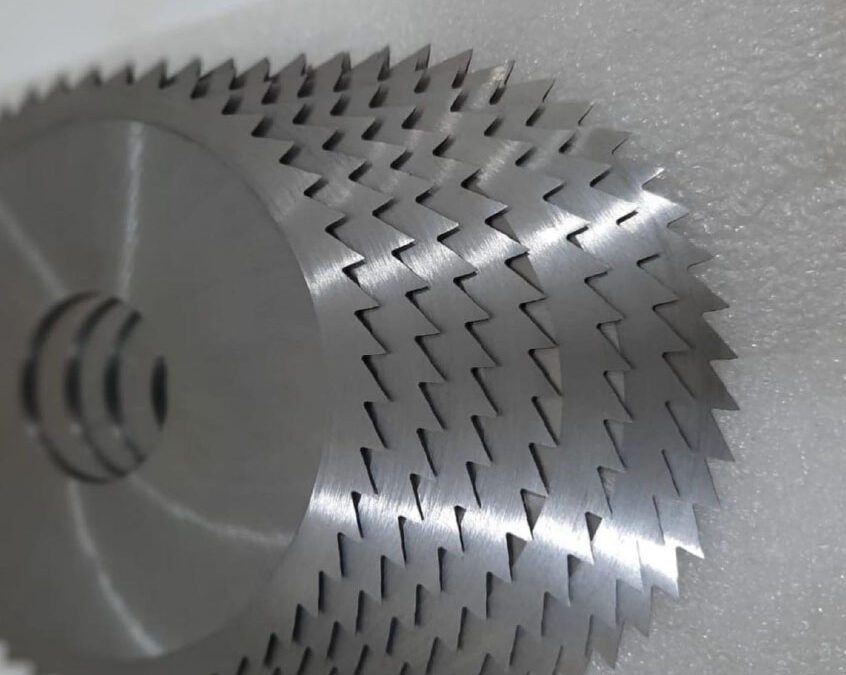

Maxwell also designs specialty blades to create a pinker type cut, perforated cut or even a scalloped edge cut. We have been supplying machine builders with score cut and crush cut knives dating back to some of the oldest slitting systems still used today!

Photos

Dec 7, 2022

Plastic shims allow precise adjustment of the cutting clearance. The main advantages of plastic shims are:

- Made of durable, wear-resistant, and oil-resistant plastic.

- Maintains size even under pressure.

- Color-coded for easy identification

- Easily converts by cutting and sliding without removing

- Width from 0.012mm to 1.50mm.

Photos

Dec 7, 2022

Paper cutters are used in paper industries. They are used for giving shapes in cigarette paper, tissue paper thread cones etc.

Advantages:

- Tight tolerances for the thinnest cuts

- High tensile strength for maximum cut times

- The thinnest surfaces for less friction and less deposition

- Excellent quality in slitting and follow-cut operations longs

Dec 7, 2022

Maxwell Tools Successfully introduced and then launched slitting saws before any other company out there.

Slitting saws are made with the highest quality steel to help customers cut off, mill, and groove steel and other alloys on all of their machines. Maxwell’s slitting saw blades come in every range of thickness and diameter customers could need. There is also a wide range of tooth forms including: A-B-BW. Maxwell wants to be sure that customers can find a slitting saw to fit all of their needs.

This is a sample of the wide selection that of slitting saws you will get when you decide to go with Maxwell:

- Screw-Slitting Saws-Tooth Form “A” – Many projects leave customers with screws all over that they need to mill. The only problem is finding the right tool to do the job; which is where the screw-slit saw comes in. This circular saw blade is all flat ground making them perfect for milling screw heads. The Maxwell screw-slitting saw are crafted with form “A” teeth to help customers create the perfect look.

- Tube Cutting Slitting Saw-Tooth From “BW” – Often times craftsmen and homeowners are confronted with pipe troubles when fixing plumbing problems. One of the most common problems is tubing that needs to be replaced which can only be done by cutting them out. Our tube cutting slitting slaw makes cutting through tubing a breeze. The secret is that these circular saws are crafted with “BW” form teeth just what customers need for cutting tubing.

- Side Chip Clearance Slitting Slaw – These slitting saws are perfect for those projects that call for deep cuts or slots. Especially those projects where side cutting chip clearance is important for managing the width of cuts and slots.

- Staggered Tooth Slitting Saw – Another excellent choice for creating deep cuts these Maxwell blades are also perfect for coarser feeds. Thanks to its helical tooth formation it can provide shearing action while still having plenty of chip space. Nowhere else will you find a staggered slitting slaw with as much quality as those provided by Maxwell Tools.

- Simple/Plain Slitting Saws – These are the most basic slitting saws on the market perfect for those simple jobs customers need done in a hurry. They are also the best choice for those who are just getting started working on more complicated projects. Maxwell also offers these slitting saws with a wide range of teeth that are available upon request.

Brief About Product

On top of the wide range of saws that are listed above Maxwell tools also offers a complete range metal working slitting saws. Offering: Rotary Shear Blades for Hot & Cold Working, HR & CR Slitting Cutters, Slitting Spacers, Paper cutting knives, Paper Trimming knives, Paper Slitting saws and Knives, Simplex/Duplex Sheet Cutter Knives, Top & Bottom Slitter Knives, Straw Cutter Knives, Slitting saws, Sheet Cutter Knives.

No matter the needs of your project you can be sure that Maxwell Tools has what you need. We have slitting saws for every possible project you have in mind.

Dec 6, 2022

Understanding the Importance of Slitter Machines in the Manufacturing Industry

Learn about Slitting Process, Roll Slitting and Slitter Rewinder

Get a comprehensive understanding of the importance of slitter machines in the manufacturing industry and how slitting, roll slitting and slitter rewinder works. Learn about different types of slitter blades and how to improve the efficiency and speed of slitting process.

Introduction:

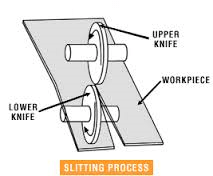

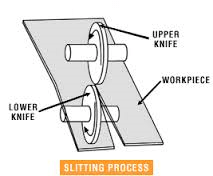

The manufacturing industry is constantly evolving and advancing, and one of the key pieces of equipment that helps to keep it running smoothly is the slitter machine. Slitter machines, also known as slitting machines or rotary slitting machines, are used to cut large rolls of materials, such as paper, film, and metal, into smaller rolls. This process is known as slitting, and it is a crucial step in many manufacturing operations.

What are slitter machines?

Slitter machines, also known as slitting machines or rotary slitting machines, are used to cut large rolls of materials, such as paper, film, and metal, into smaller rolls. This process is known as slitting, and it is a crucial step in many manufacturing operations.

Importance of precision

One of the most important aspects of a slitter machine is its precision. These machines must be able to accurately and consistently cut materials to the desired width, without causing any damage or defects. This is why the quality of the slitter blade is so important.

Types of slitter blades

- High speed steel blades

- Carbide blades

- Ceramic blades

The slitter machine’s blades are made from a variety of materials, such as high speed steel, carbide, and ceramics, each with their own properties that suit for specific material. Each blade is designed to handle a specific type of material and must be regularly maintained to ensure optimal performance.

Efficiency and Speed

Another important aspect of slitter machines is their speed and efficiency. These machines must be able to quickly and efficiently process large volumes of material in order to keep up with the demands of the manufacturing industry. This is why many slitter machines are now equipped with advanced technologies, such as automation and computerized controls, to help increase their productivity and performance.

Learn about slitting process, roll slitting and slitter rewinder

Slitter rewinder machine plays an important role in roll slitting process, this machine rewind the slitted rolls into smaller sizes. To learn more about the slitting process and how it works, check out this article on our website.

Conclusion:

In conclusion, slitter machines play a vital role in the manufacturing industry. They are used to convert large rolls of material into smaller sizes, and their precision, speed, and efficiency make them an essential piece of equipment for any manufacturing operation. It’s important to have a well-maintained slitter machine with high-quality blades, as well as to take advantage of advanced technologies to stay competitive in the market.