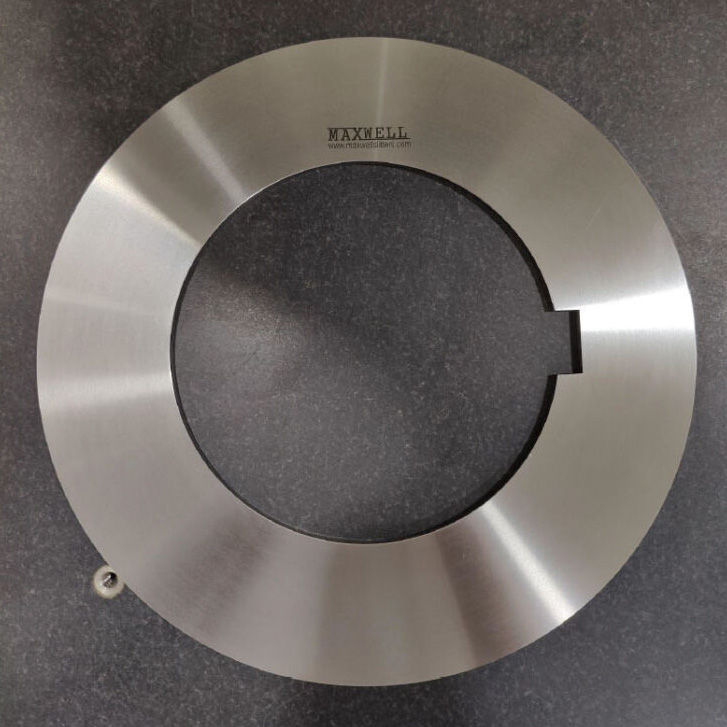

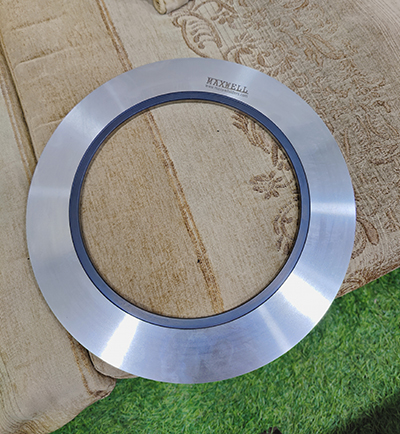

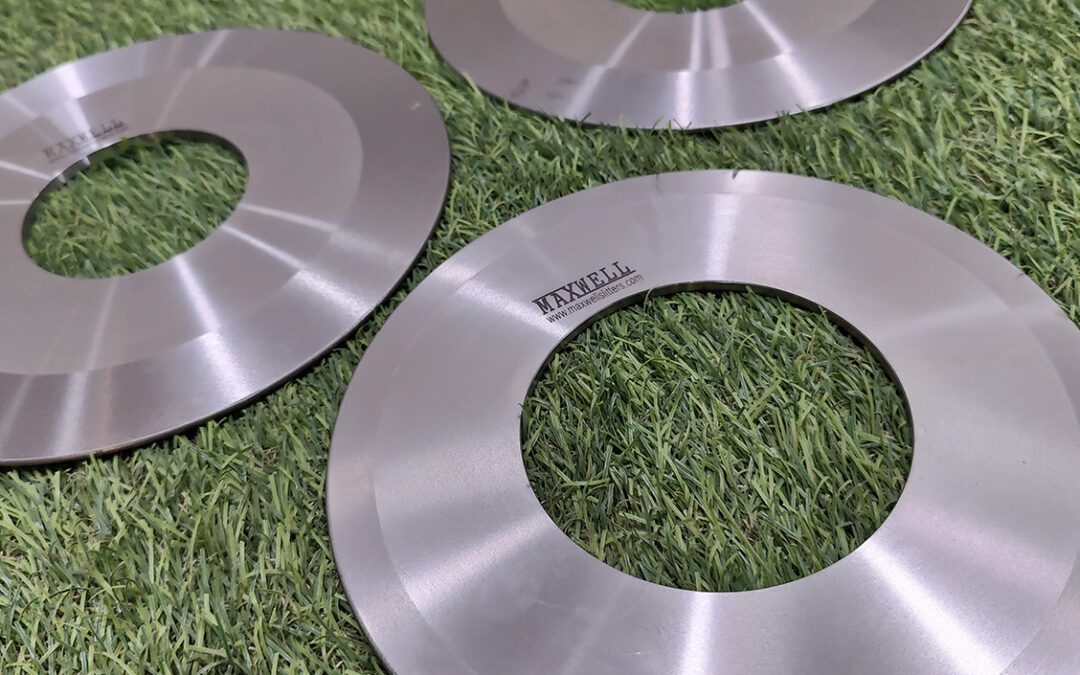

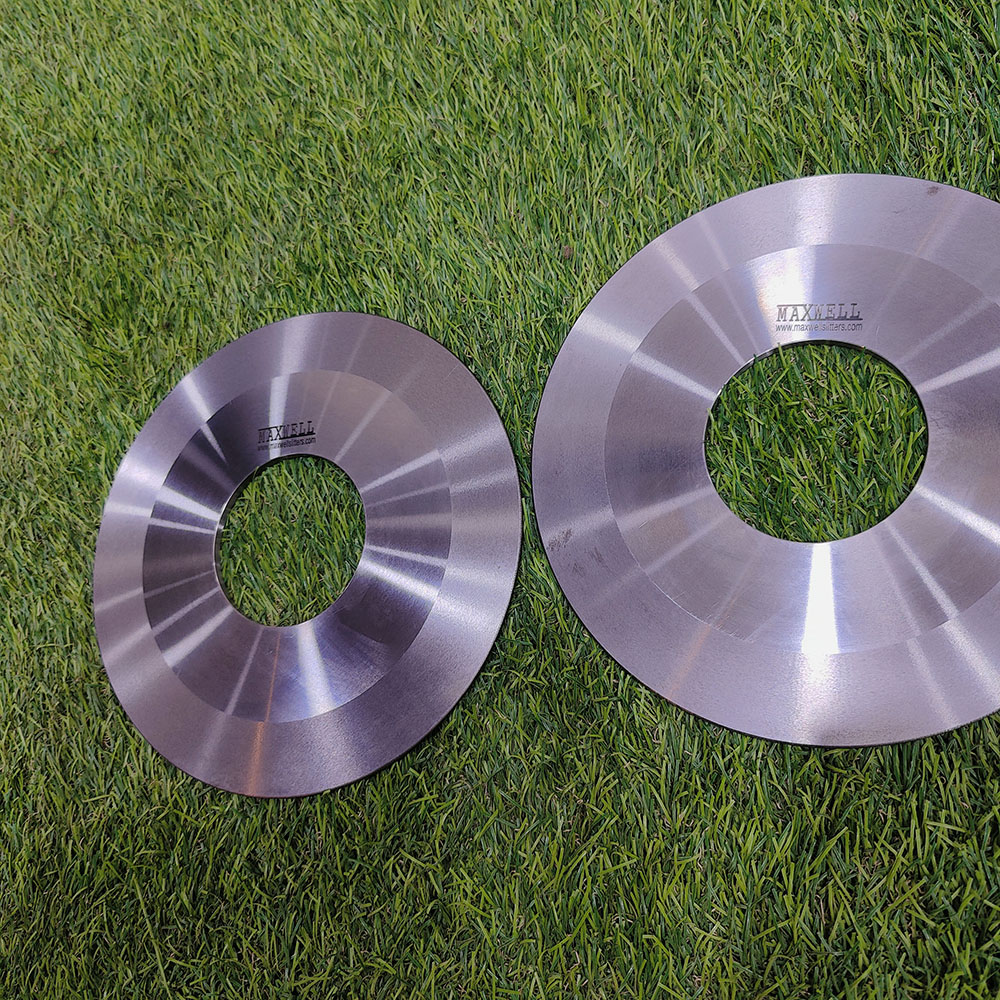

Slitting Saw

The Ultimate Guide to Slitting Saws: What They Are and How to Use Them

A slitting saw is a type of cutting tool that is used to make precise cuts in a variety of materials. These saws are specially designed to cut thin, flat materials such as sheet metal, plastic, and wood. They are an essential tool for any metalworking or woodworking shop and are commonly used for tasks such as cutting sheet metal for HVAC ductwork, making custom parts, and slicing through thick boards to create thinner planks.

What is a Slitting Saw?

A slitting saw is a circular saw blade that is specifically designed to make cuts parallel to the axis of the blade. These saws are typically made from high-speed steel or carbide and come in a wide range of diameters and thicknesses. They are usually mounted on an arbor or spindle and can be powered by a variety of different machines, including milling machines, drill presses, and specialized slitting saw machines.

How Does a Slitting Saw Work?

Slitting saws work by rotating at high speeds and cutting through materials as they pass over the blade. The saw blade is typically mounted on an arbor, which is inserted into the machine and held in place by a set of bearings. As the arbor spins, the saw blade cuts through the material, creating a clean, precise cut.

How Does a Slitting Saw Work?

Slitting saws work by rotating at high speeds and cutting through materials as they pass over the blade. The saw blade is typically mounted on an arbor, which is inserted into the machine and held in place by a set of bearings. As the arbor spins, the saw blade cuts through the material, creating a clean, precise cut.

Types of Slitting Saws

There are a few different types of slitting saws available on the market, each with its own specific uses and features.

HSS Slitting Saw

HSS (high-speed steel) slitting saws are the most common type of slitting saw. They are made from a high-speed steel alloy, which is extremely durable and can withstand high temperatures. HSS slitting saws are great for cutting through a variety of materials, including steel, aluminum, and plastic.

Carbide Tipped Slitting Saw

Carbide-tipped slitting saws are another popular type of slitting saw. They are made by brazing a small piece of carbide to the edge of a steel saw blade. Carbide is a much harder material than high-speed steel and can hold a sharper edge for longer periods of time. This makes carbide-tipped slitting saws perfect for cutting through very hard materials, such as titanium and stainless steel.

Inserted Tooth Slitting Saw

Inserted tooth-slitting saws are a variation on the carbide-tipped saw. Instead of brazing a single piece of carbide to the edge of the blade, these saws have multiple carbide inserts that are held in place by a small set screw. This allows the carbide teeth to be replaced as they wear down, which greatly extends the life of the saw.

How to Use a Slitting Saw

Using a slitting saw is relatively simple, but it does require a certain level of skill and attention to detail. Before starting a cut, ensure the saw blade is properly mounted and tightened on the arbor. Next, position the material to be cut against the saw blade and clamp it securely in place.

When ready to make the cut, turn on the machine and allow the saw blade to reach its full speed. Slowly lower the blade into the material and begin cutting, making sure to keep your fingers and other body parts well away from the saw blade. Once the cut is complete, turn off the machine and carefully remove the cut piece from the machine.

It is important to always wear the appropriate safety gear when using a slitting saw, including safety goggles or a face shield, gloves, and hearing protection. Additionally, make sure to keep the saw blade and machine clean and well-maintained to ensure smooth and accurate cuts.

Conclusion

Slitting saws are a versatile and essential tool for any metalworking or woodworking shop. With a wide range of types and sizes available, these saws can be used to make precise cuts in a variety of materials. By understanding the different types of slitting saws and how to use them properly, you’ll be able to tackle any project that comes your way.