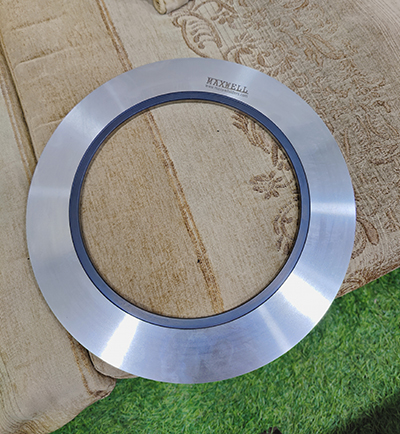

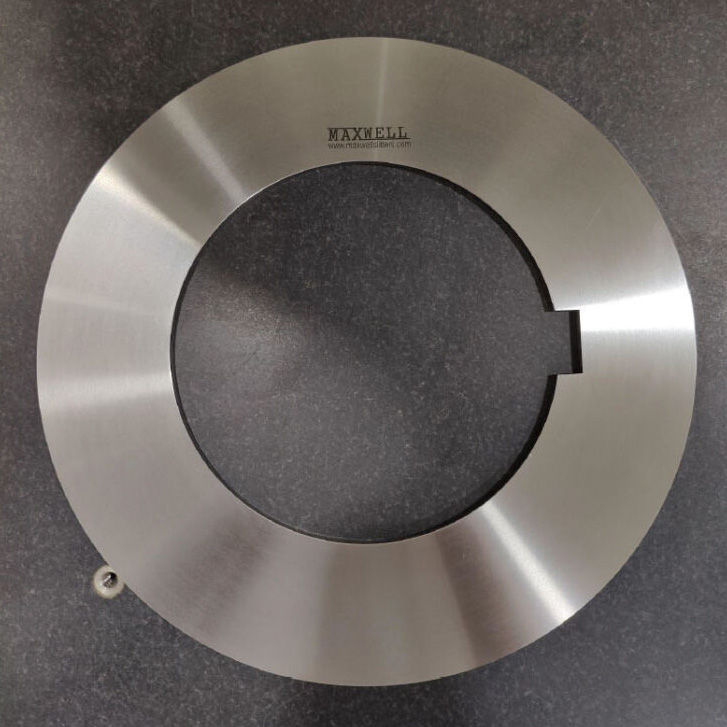

Rotary Slitter Cutters

Rotary Slitter Cutters

Product Code: MXS 02

Material: D2, H13, SKD11

Circular knives also called round knives & Rotary Slitter Knives are characterized by their mostly circular shape with corresponding diameter Ø. Their cutting geometries are either flat, slotted, or toothed cutting edge. The cutting motion is mostly rotating or stationary. They are used for multiple purposes like sheet metal cutting and coil slitting.

Available in D2,D3,HSS,H11,H13

- Used for Slitting & trimming mild steel, CRGO, CRNGO, Stainless Steel, Aluminium, Brass & Copper

- Sharp, uniform shearing edge after regrinding.

- Thickness tolerance 0.0015mm; Flatness tolerance 0.001mm (depends on OD & thickness)

- Lapping for finish up to 0.2 Ra

- Manufacture up to 600mm OD

- Optimum hardness for wear resistance

- Cutting capacity range: 0.1mm to 24mm thick strip

- Surface finish: ground, lapped and polished.