Feb 6, 2024

Maxwell offers spacers made out of hardened alloyed tool steel with stainless steel characteristics. These metal spacers are used on slitter machine to adjust distance between slitting knives according to needed width of coiling strips.

Advantages

- Available in thickness from 3 to 100mm

- Tolerance up to ± 0.0005 mm

- Lighter weight for easy assembling

- Lateral surfaces are lapped, ground and polished

Photos

Feb 6, 2024

Rubber Bonded Spacers are used along with rotary slitter knives and are manufactured for stability and precision tolerances from synthetic rubber to prevent metal strips from scratching during trimming or cutting applications.

Advantages

- Rubber Material(Polyurethane or Nitrile)

- Hardness 60 to 95 Shore A

- Color Coded for differentiation

- High precision and excellent tensile strength

- Thickness tolerance up to ± 0.0005 mm

Photos

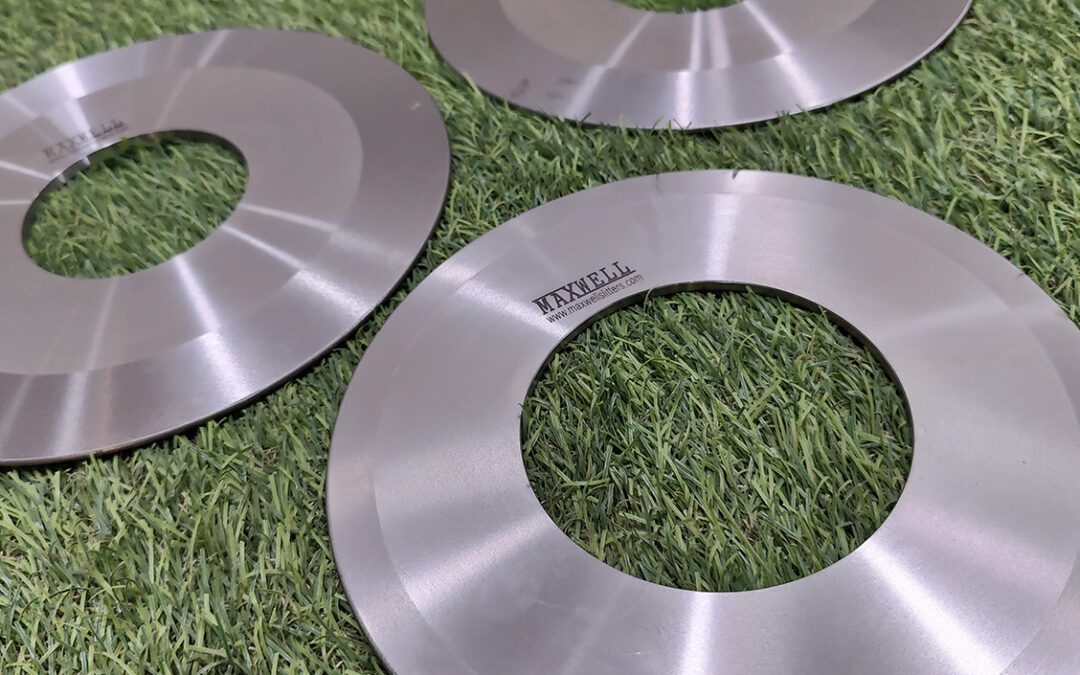

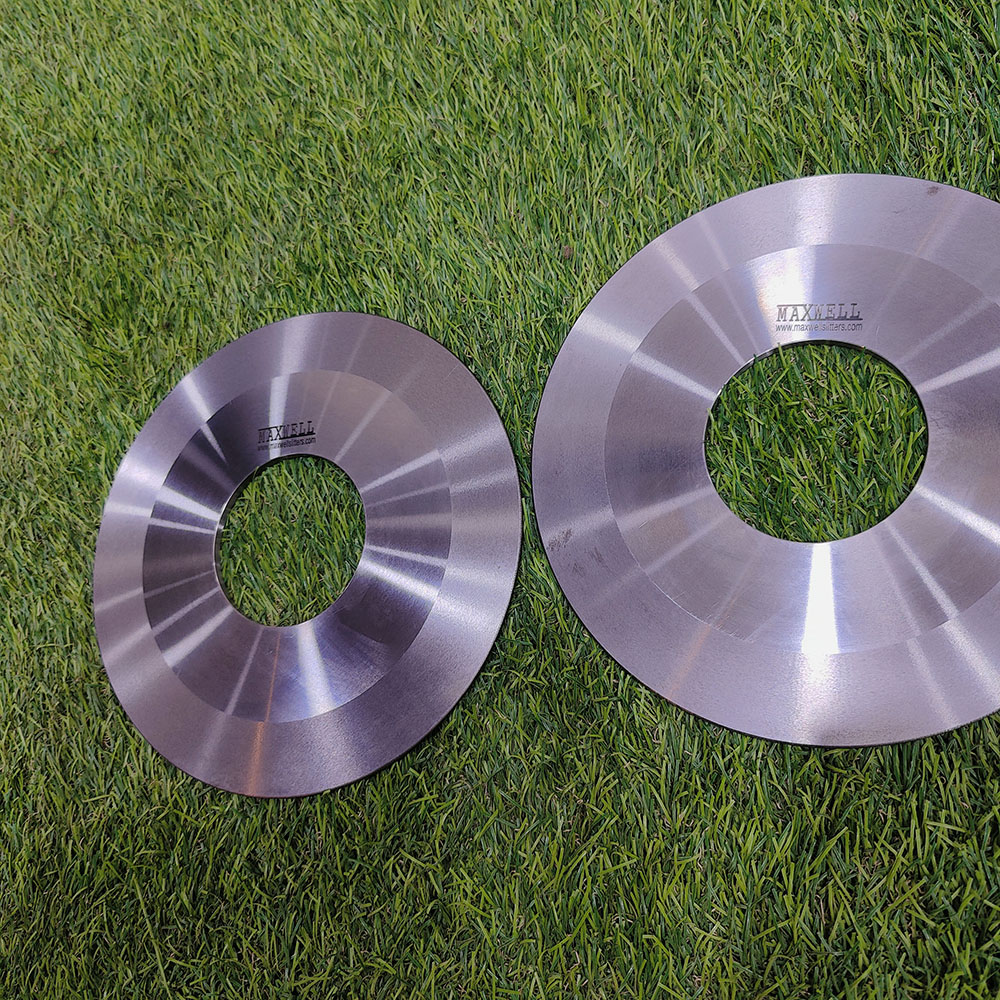

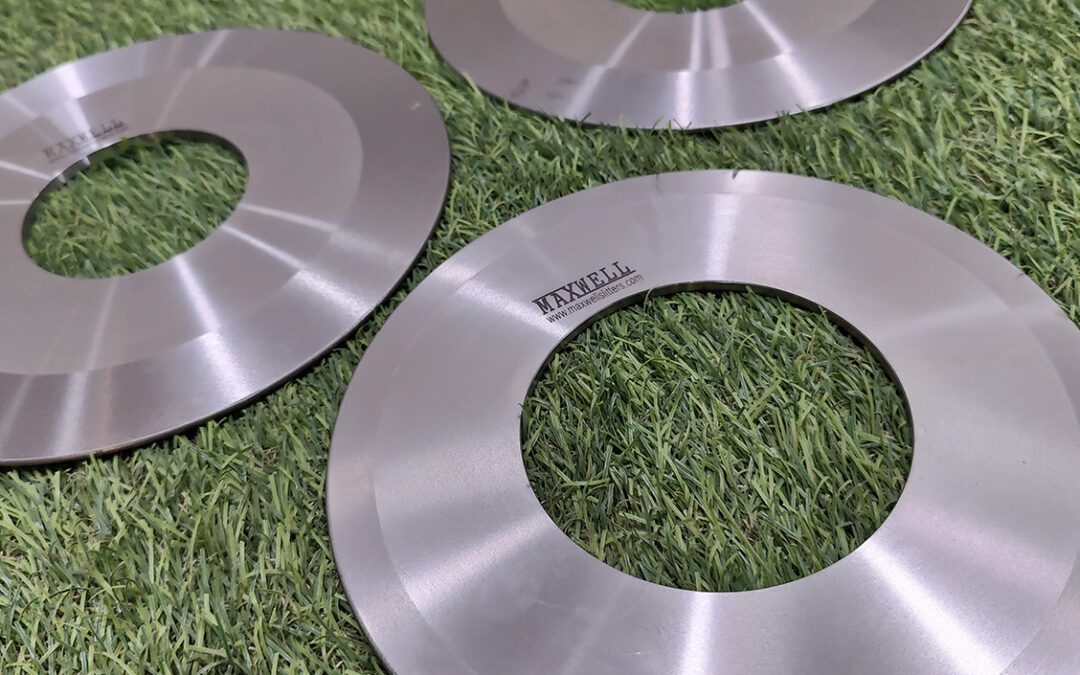

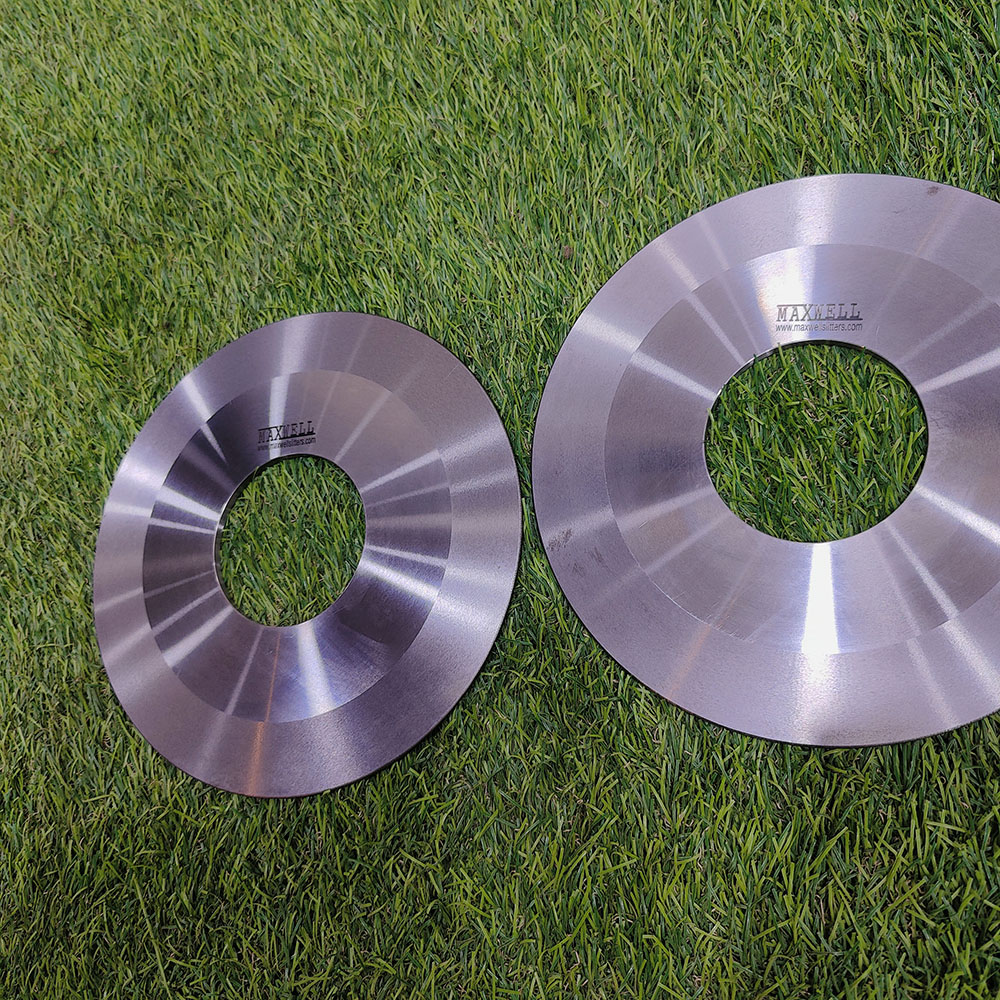

Dec 7, 2022

These discs ensure clear separation and guidance of the cut material strips and uniform winding of the strips onto the recoiler of the slitting line:

Advantages

- Single & Double Angle and various thickness

- Top-quality steel with high wear resistance

- Chrome plating option available to reduce friction

Photos

Dec 7, 2022

Hard alloy steel tool steel stripping rings are used for the thinnest materials and narrowest strips as long as the slitting design permits such use.

Rubber Bonded(Polyurethane) stripper rings are specifically designed for ultra-sensitive surfaces.

Dec 7, 2022

Maxwell also designs specialty blades to create a pinker type cut, perforated cut or even a scalloped edge cut. We have been supplying machine builders with score cut and crush cut knives dating back to some of the oldest slitting systems still used today!

Photos

Dec 7, 2022

Plastic shims allow precise adjustment of the cutting clearance. The main advantages of plastic shims are:

- Made of durable, wear-resistant, and oil-resistant plastic.

- Maintains size even under pressure.

- Color-coded for easy identification

- Easily converts by cutting and sliding without removing

- Width from 0.012mm to 1.50mm.

Photos