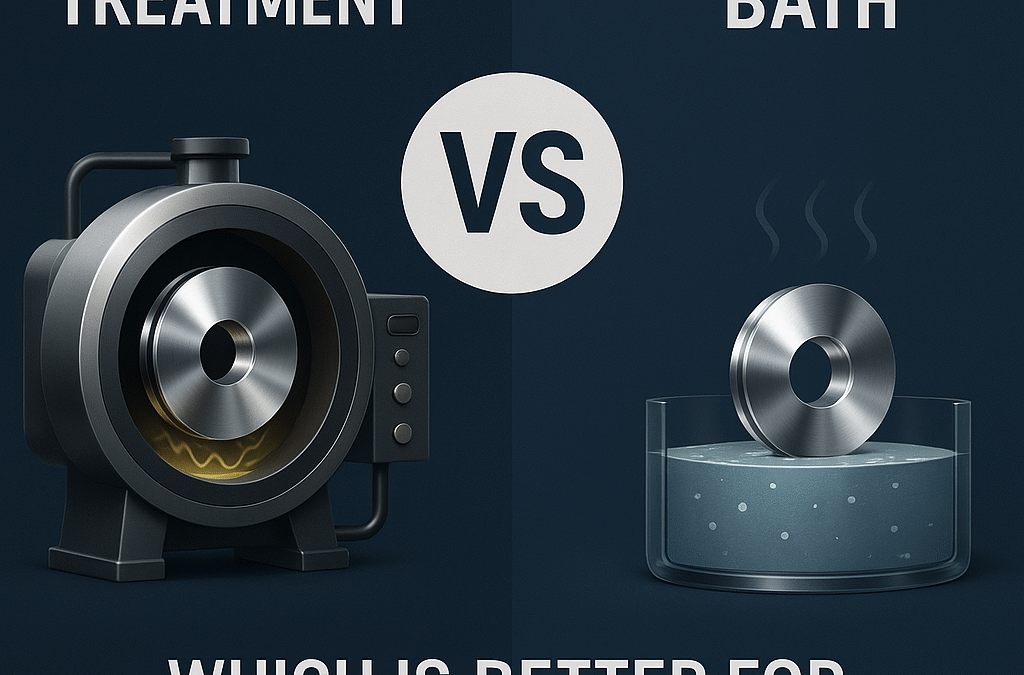

Vacuum Heat Treatment vs Salt Bath – Which is Better for Rotary Slitter Knives?

Maxwell Slitter Industries is the world’s #1 manufacturer of rotary slitter knives, powered by our vacuum hardening process that delivers unmatched hardness, edge life, and cutting precision.

When selecting rotary slitter knives for your slitting line, one critical factor that determines their performance is the heat treatment process. The right treatment not only improves hardness but also extends edge life, reduces maintenance, and enhances cutting precision.

Two popular methods—Vacuum Heat Treatment (VHT) and Salt Bath Heat Treatment (SBHT)—are widely used in the industry. But which one truly delivers better performance for rotary slitter knives? Let’s find out.

Why Heat Treatment Matters for Slitter Knives

Rotary slitter knives undergo intense cutting forces and high friction during coil slitting operations. Without proper hardening, they lose sharpness quickly, resulting in:

● Poor cut quality

● Frequent regrinding and replacements

● Increased downtime and operational costs

Choosing the right heat treatment ensures:

● Uniform hardness

● Superior edge retention

● Longer service life

● Dimensional stability

Vacuum Heat Treatment (VHT) – The Premium Choice

Vacuum Heat Treatment is a modern process carried out in a controlled vacuum furnace. By eliminating oxygen it prevents surface oxidation and produces a clean, bright finish.

Advantages of VHT

● Oxidation-free surface – no scaling or decarburization

● Minimal distortion – perfect for tight tolerances

● Superior wear resistance – refined microstructure for long-lasting performance

● Environmentally friendly – no harmful residues

For high-precision applications like rotary slitter knives, VHT ensures maximum durability and consistent cutting results.

Salt Bath Heat Treatment (SBHT) – The Traditional Approach

Salt Bath Heat Treatment involves immersing knives in molten salt for heating and quenching. It remains widely used due to its cost-effectiveness and fast processing.

Advantages of SBHT

● Rapid, uniform heating reduces cracking risks

● Good hardness for general applications

● Lower cost compared to vacuum treatment

Limitations

● Leaves salt residues requiring cleaning

● Higher risk of distortion during quenching

● Shorter edge life under demanding conditions

Direct Comparison: Vacuum vs Salt Bath

| Feature | Vacuum Heat Treatment | Salt Bath Heat Treatment |

| Surface Quality | Clean, bright, oxidation-free | May have oxide and salt residue |

| Dimensional Stability | Excellent – minimal distortion | Moderate – needs post-processing |

| Edge Retention | Superior – stays sharp longer | Wears faster under stress |

| Tool Life | Longer – ideal for high-speed lines | Shorter in demanding operations |

| Environmental Impact | Eco-friendly | Salt disposal concerns |

| Cost | Higher | Lower |

Which Heat Treatment Should You Choose?

For rotary slitter knives where precision, consistency, and longer life are essential, Vacuum Heat Treatment is the clear winner. It ensures better performance, less downtime, and higher productivity compared to salt bath-treated knives.

Salt Bath may still be used for cost-sensitive applications, but it lacks the superior edge retention and stability offered by VHT.

Why Maxwell Leads the Industry

At Maxwell Slitter Industries, we don’t just use vacuum heat treatment—we have perfected it with a hardening recipe that makes our blades outperform all others.

What Sets Maxwell Apart

● Vacuum Hardening Technology – unmatched hardness & wear resistance

● Custom Engineering – made to exact OEM specifications

● Trusted Worldwide – by leading slitting line manufacturers

● In-House Expertise – end-to-end control ensures consistent quality

Explore our full range of Rotary Slitter Knives