No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

A slitting saw is a type of cutting tool that is used to make precise cuts in a variety of materials. These saws are specially designed to cut thin, flat materials such as sheet metal, plastic, and wood. They are an essential tool for any metalworking or woodworking shop and are commonly used for tasks such as cutting sheet metal for HVAC ductwork, making custom parts, and slicing through thick boards to create thinner planks.

👉 Looking to purchase a high-performance slitting saw? Click here to explore our range.

A slitting saw is a circular saw blade that is specifically designed to make cuts parallel to the axis of the blade. These saws are typically made from high-speed steel or carbide and come in a wide range of diameters and thicknesses. They are usually mounted on an arbor or spindle and can be powered by a variety of different machines, including milling machines, drill presses, and specialized slitting saw machines.

Slitting saws work by rotating at high speeds and cutting through materials as they pass over the blade. The saw blade is typically mounted on an arbor, which is inserted into the machine and held in place by a set of bearings. As the arbor spins, the saw blade cuts through the material, creating a clean, precise cut.

Slitting saws work by rotating at high speeds and cutting through materials as they pass over the blade. The saw blade is typically mounted on an arbor, which is inserted into the machine and held in place by a set of bearings. As the arbor spins, the saw blade cuts through the material, creating a clean, precise cut.

Types of Slitting Saws

There are a few different types of slitting saws available on the market, each with its own specific uses and features.

HSS Slitting Saw

HSS (high-speed steel) slitting saws are the most common type of slitting saw. They are made from a high-speed steel alloy, which is extremely durable and can withstand high temperatures. HSS slitting saws are great for cutting through a variety of materials, including steel, aluminum, and plastic.

Carbide Tipped Slitting Saw

Carbide-tipped slitting saws are another popular type of slitting saw. They are made by brazing a small piece of carbide to the edge of a steel saw blade. Carbide is a much harder material than high-speed steel and can hold a sharper edge for longer periods of time. This makes carbide-tipped slitting saws perfect for cutting through very hard materials, such as titanium and stainless steel.

Inserted Tooth Slitting Saw

Inserted tooth-slitting saws are a variation on the carbide-tipped saw. Instead of brazing a single piece of carbide to the edge of the blade, these saws have multiple carbide inserts that are held in place by a small set screw. This allows the carbide teeth to be replaced as they wear down, which greatly extends the life of the saw.

Using a slitting saw is relatively simple, but it does require a certain level of skill and attention to detail. Before starting a cut, ensure the saw blade is properly mounted and tightened on the arbor. Next, position the material to be cut against the saw blade and clamp it securely in place.

When ready to make the cut, turn on the machine and allow the saw blade to reach its full speed. Slowly lower the blade into the material and begin cutting, making sure to keep your fingers and other body parts well away from the saw blade. Once the cut is complete, turn off the machine and carefully remove the cut piece from the machine.

It is important to always wear the appropriate safety gear when using a slitting saw, including safety goggles or a face shield, gloves, and hearing protection. Additionally, make sure to keep the saw blade and machine clean and well-maintained to ensure smooth and accurate cuts.

Slitting saws are a versatile and essential tool for any metalworking or woodworking shop. With a wide range of types and sizes available, these saws can be used to make precise cuts in a variety of materials. By understanding the different types of slitting saws and how to use them properly, you’ll be able to tackle any project that comes your way.

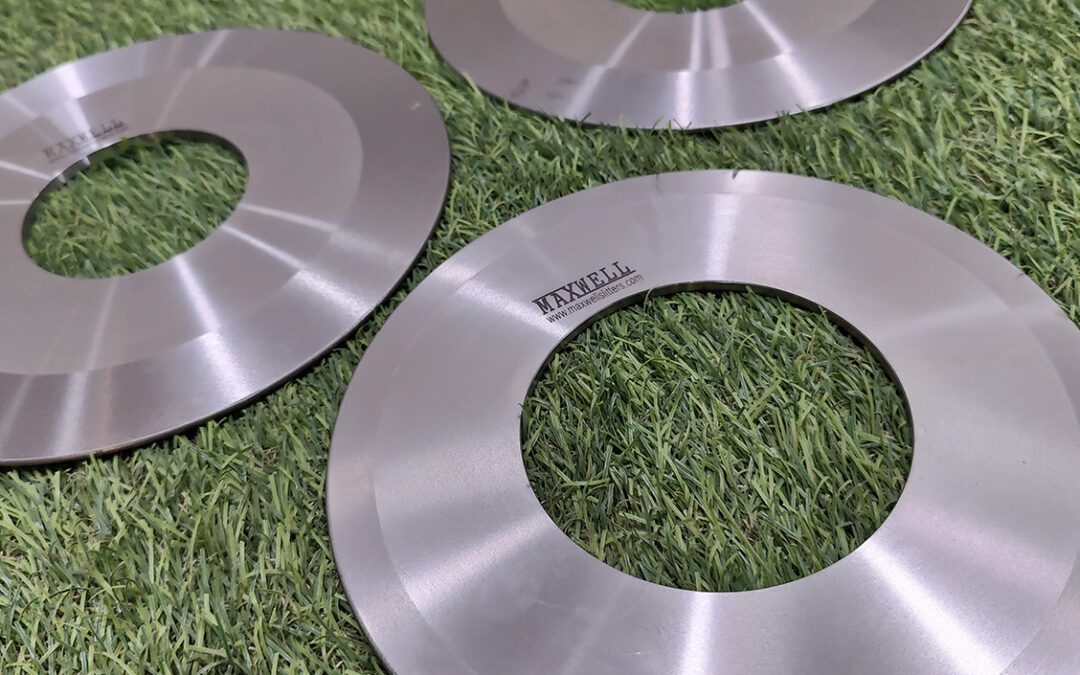

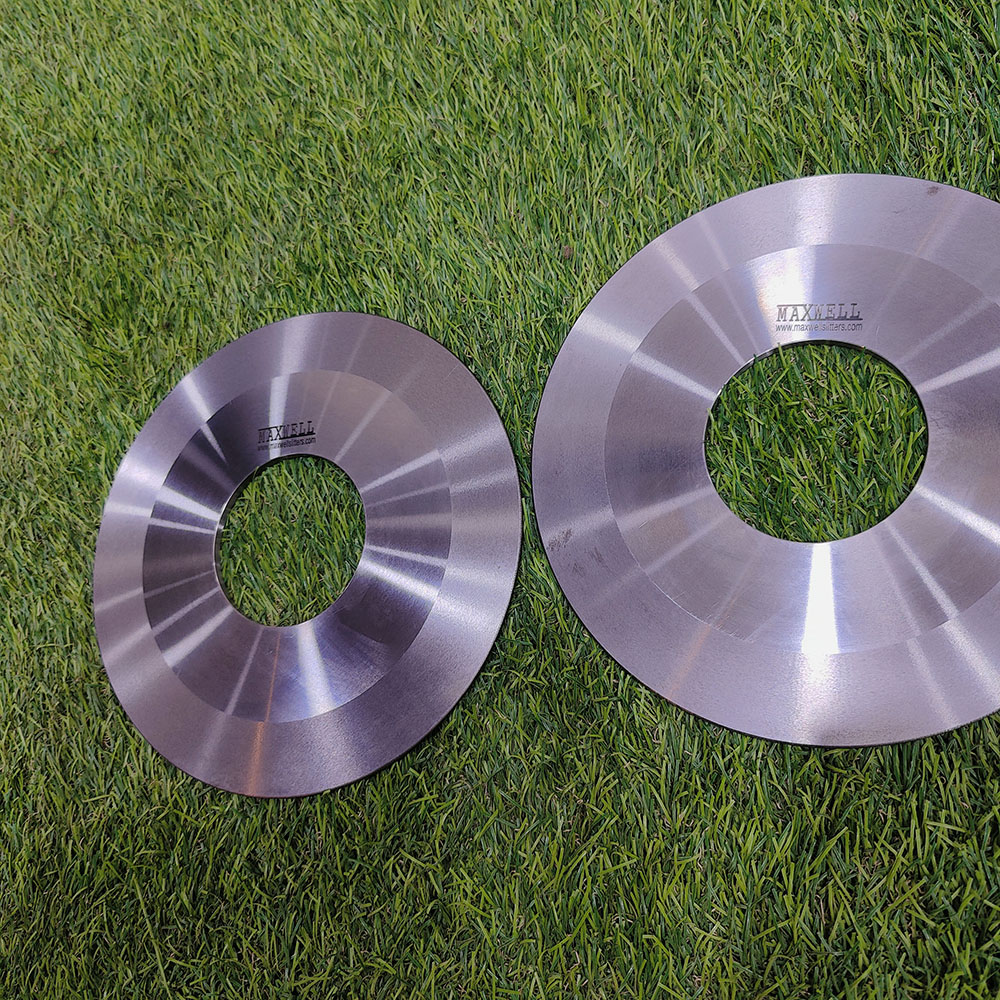

At Maxwell Slitters, we specialize in manufacturing high-quality rotary slitter blades and knives that meet the demanding needs of various industries. Our products are engineered for precision, durability, and performance, ensuring that your cutting operations run smoothly and efficiently. Whether you’re working with paper, film, foil, or metal, our rotary slitter blades deliver clean, precise cuts every time.

Rotary slitter blades, also known as rotary slitting knives, are specialized cutting tools used in slitting machines to cut large rolls of material into narrower widths. They are crucial in industries such as paper, plastic film, metal, textiles, and packaging. Our rotary slitter blades feature a circular design with a sharp cutting edge, often equipped with multiple cutting teeth or serrations for enhanced performance.

The slitting process involves feeding the material through a slitting machine where the rotating blade makes precise cuts. Proper maintenance, including regular sharpening, is essential to ensure consistent cutting quality and efficiency.

Our rotary slitter blades are crafted with the highest standards of quality and precision. Here are the key features and specifications:

Our rotary slitter blades are versatile and can be used across a wide range of industries and materials, including:

Crafted from high-grade tool steels for unmatched durability and sharpness.

Designed with ±0.0015mm thickness tolerance for consistent, clean cuts.

Tailored slitter blades and knives to meet your specific industry needs.

Reliable shipping with 2-4 week lead times for international orders.

Maxwell Slitter is a top manufacturer and supplier of standard and custom size precision circular slitter knives and rotary slitting blades. Each blade is the result of expert craftsmanship, premium materials, and a deep understanding of slitting dynamics. From high-speed converting lines to heavy-duty metal processing, our blades are built to handle it all with clean cuts, extended lifespan, and exceptional consistency.

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

Slitter blades and knives are specialized cutting tools used in slitting machines to precisely cut large rolls of material into narrower strips.

Slitter blades are commonly used in industries like paper, plastic film, metal, textiles, and packaging, these blades ensure clean, accurate cuts with minimal material waste.

Slitting blades are typically manufactured from high-performance materials such as tool steel, high-speed steel (HSS), stainless steel, and tungsten carbide.

Yes, absolutely! At Maxwell Slitter, we specialize in manufacturing custom-sized slitter blades of different shapes and sizes including: rotary, circular and straight machine knives.

Rotary slitter blades are used to slit large rolls of material into narrower widths. They are essential in industries such as paper, plastic film, metal, textiles, and packaging.

The lifespan of our blades depends on usage, the material being cut, and maintenance. However, our high-quality materials and precise manufacturing ensure extended lifespan compared to standard blades.

Our blades are designed to be compatible with a wide range of slitting machines. For custom applications, we can manufacture blades to your specific specifications.

Product Code: MXS 03

Material: D2, D3, H13, H11

Our Metal Shearing blades are indispensable tools offering clean, precise, and efficient cutting solutions. Designed for heavy-duty applications, these machine blades and knives ensure optimal performance and durability. We offer our metal shears in single-edge, two-edge, father custom configurations. Choose from our available designs or share your custom requirement for the manufacturing.

Shearing blades are straight or curved cutting tools used in guillotine and shear cutting machines. These tools are engineered to provide accurate cuts for various materials, including metal, rubber, paper, and plastic. With advanced manufacturing techniques, Maxwell ensures that their shearing blades maintain sharpness and durability, meeting the rigorous demands of industrial applications.

Maxwell Slitter Ind. offers a wide range of shearing blades, including:

1. Flat Shear Blades: Ideal for cutting metal sheets with precision and smoothness.

2. Circular Saw Knives: Used for slicing and cutting in industries such as metal processing and paper production.

3. Horizontal Shear Knives: Designed for heavy-duty shearing tasks in steel mills and processing plants.

1. High-Grade Materials: Manufactured using premium steel alloys for enhanced strength and longevity.

2. Precision Engineering: Advanced CNC machining ensures exact specifications and superior cutting accuracy.

3. Vacuum Heat Treatment: Improves blade hardness, wear resistance, and overall performance.

4. Custom Configurations: Available in various sizes and designs to meet specific industrial requirements

1. Metal Processing: Cutting steel sheets, aluminum plates, and other metals in automotive and construction industries.

2. Paper Production: Trimming and cutting paper rolls into precise sizes for packaging and printing.

3. Rubber Processing: Efficiently slicing rubber sheets and molded components.

4. Plastic Manufacturing: Cutting plastic films, sheets, and other materials with minimal waste.

5. Recycling: Shearing metal and plastic scrap into manageable sizes for recycling processes.

Maxwell Slitter Ind. is a trusted shear knives manufacturer, exporter, and supplier. Industries rely on Maxwell for:

1. Superior Quality: Products crafted from the finest materials using cutting-edge technology.

2. Durable Solutions: Rigorous quality checks and heat treatments ensure long lasting performance.

3. Tailored Designs: Customizable options for unique operational needs.

4. Competitive Pricing: High-quality blades offered at cost-effective rates.

5. Expert Support: A team of experienced professionals providing guidance and assistance.

As a leading shear blades manufacturer, exporter, and supplier, Maxwell specializes in products like shear knives, shear blades, shearing knives, and circular saw knives. Their offerings cater to diverse industries,

making them a one-stop solution for all cutting tool requirements.

Maxwell’s shearing blades stand out for their unmatched quality and performance, ensuring efficiency and productivity in every application. Trust Maxwell for your industrial cutting tool needs and experience the difference in quality and service.

They are widely used in industrial operations for trimming, slitting, blanking, and cropping, helping to shape metal into desired sizes and forms for manufacturing and fabrication processes.

Our machine shearing blades are designed for durability and high performance. Their lifespan typically depends on the type of material being cut, the frequency of use, and maintenance practices.

Shear blades are usually made from high-quality tool steels or alloy steels such as H13, H-11, D2, or HSS. These materials offer excellent hardness, wear resistance, and toughness

Yes, you can order custom-sized shearing blades. Provide detailed specifications or requirements and we will help ensure a precise fit for your machinery.

These discs ensure clear separation and guidance of the cut material strips and uniform winding of the strips onto the recoiler of the slitting line:

Advantages

Hard alloy steel tool steel stripping rings are used for the thinnest materials and narrowest strips as long as the slitting design permits such use.

Rubber Bonded(Polyurethane) stripper rings are specifically designed for ultra-sensitive surfaces.